EBIL TECH Multi shuttle intensive storage + goods-to-person picking

Multi shuttle are popular in many industries with it’s unique advantages, such as medicine, food, clothing, auto parts, chemical and other industries. Its advantages are mainly reflected in the following points:

1. The processing capacity is more than 10 times that of traditional warehouses.

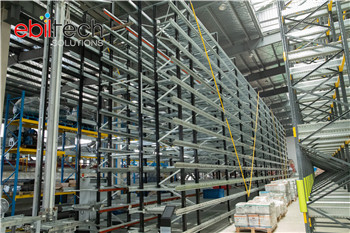

2. The multi shuttle system can be implemented anywhere on the top and bottom of racking system and in the top space to optimize the existing warehouse space. It can optimize the existing warehouse space.

3. It supports multiple storage and processing of goods. Goods of different sizes can be stored in non-fixed cargo positions after packaging. The lifting connects the upper and lower stations to ensure maximum storage density and space utilization.

4. It supports multiple storage and processing of goods. Goods of different sizes can be stored in non-fixed cargo positions after packaging. The lifting function connects the upper and lower stations to ensure maximum storage density and space utilization.

5. The same interchangeable means of transport ensure rapid replacement. The working platform in the tunnel allows operators to safely access the goods and is also convenient for maintenance

6. Easily add more shuttles at any level in further increase the processing capacity

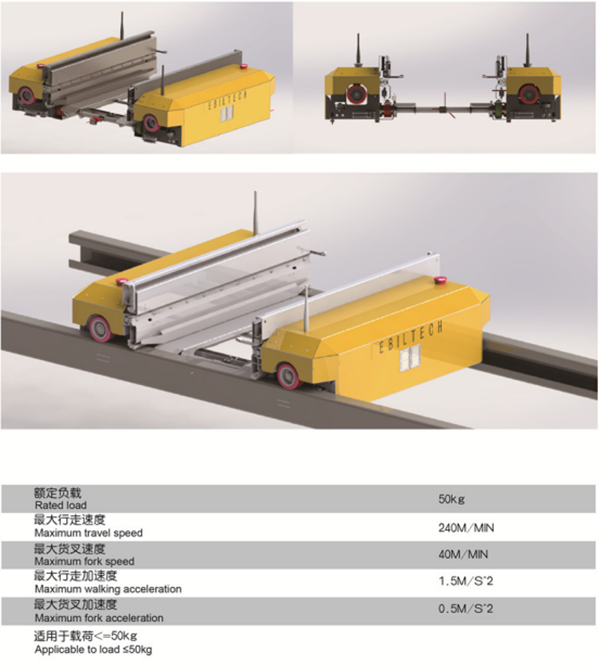

EBILTECH Multi shuttel system is an automated shuttle system for storage of small loads. The shuttle system is designed for applications where high throughput and excellent availability are essential, for example in Retail & E-commerce for returns handling, replenishment or buffer for order consolidation. The shuttle offers double to quadruple deep storage of totes, trays and cartons. EBILTECH Multi shuttel system is suitable for chilled storage environments. To reduce the number of aisles, the shuttle can be built up to 150 m long and 25 m high.

The "goods-to-person" function has gradually become the focus of attention in the industry by virtue of its significant advantages in improving picking efficiency, reducing labor intensity, and reducing the number of employees. Among them, the shuttle "goods-to-person" function has become the best way to sort out parts due to its outstanding advantages such as low energy consumption, high efficiency, and flexible operation. Therefore, it has been widely used in many industries.

Goods - to - person

1. Inventory is received at decanting workstations where operators scan bar codes and transfer items into inventory totes.

2. Inventory totes are conveyed and automatically stored in the high-density storage buffer.

3. When needed, inventory totes are retrieved and directed to picking stations.

4. Lights and graphical instructions direct operators to pick the required items from the inventory totes and place them into order containers.

5. When an order container is complete, it is automatically routed to the packing area.

6. Inventory totes return to the high-density storage buffer.

EBIL TECH has excellent technical team, high quality management personnel. A large amount of research and development funds are invested every year, it always attach importance to product innovation and R&D and constantly increase the investment in R&D of automation products. It has created a variety of automated storage equipment and systems such as radio shuttle, multi-layer shuttle, shuttle carrier, four-way shuttle, stacker, elevator, WMS and WCS etc. It has obtained a number of national patents.